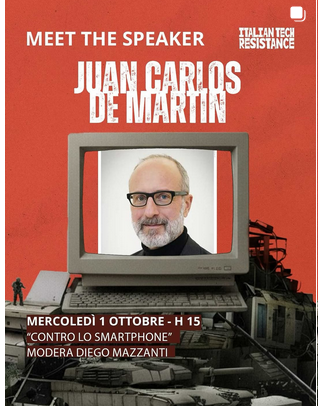

Some of the #ItalianTechResistanceTalks: #JuanCarlosDeMartin and @avilarenata No other force is transforming the world as radically as technology.

Uncategorized

1

Posts

1

Posters

5

Views

-

Some of the #ItalianTechResistanceTalks:

#JuanCarlosDeMartin and @avilarenataNo other force is transforming the world as radically as technology. For better or for worse.

We CANNOT leave Technology to the Lords of @avilarenata