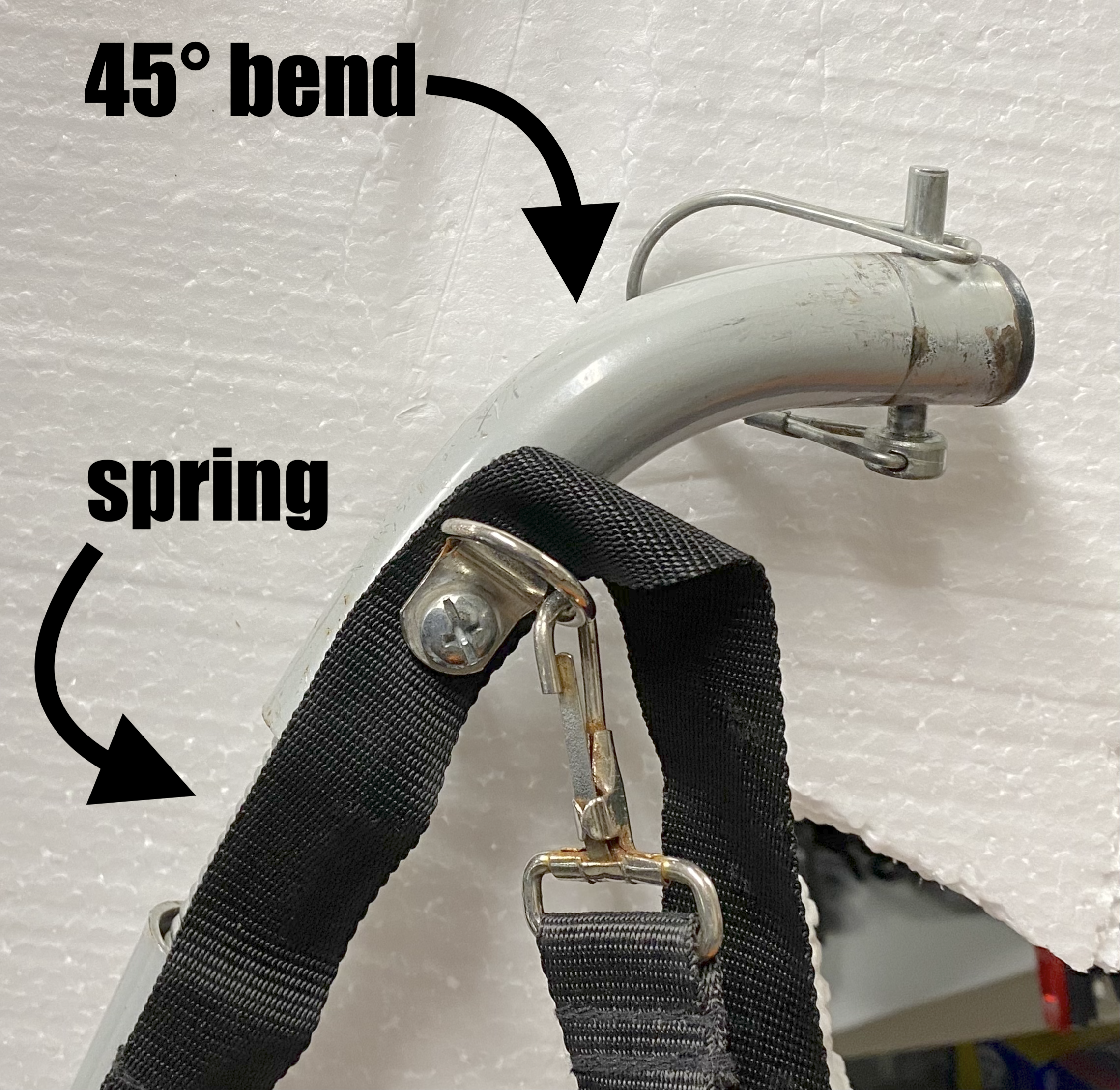

This part - the part above the spring, with the 45° bend - is on the first trailer I made.

-

One thing that's confusing me is that the short straight end piece this trailer came with seems to be intended to connect to this kind of hitch, not the kind I have:

But that's not the kind it came with, or the kind I have on my bike right now. It came with this kind, which _is_ the kind I have on my bike right now:

-

But that's not the kind it came with, or the kind I have on my bike right now. It came with this kind, which _is_ the kind I have on my bike right now:

A 1" pipe-shaped trailer hitch can fit into either of these bike-side trailer hitches, in theory - the diametres all work.

EXCEPT

...for the problem where the angles don't match so it doesn't work. The latter one expects to connect to something with a 45° angle mid-connector, and the former expects a straight-on connector, and no such additional bend.

-

A 1" pipe-shaped trailer hitch can fit into either of these bike-side trailer hitches, in theory - the diametres all work.

EXCEPT

...for the problem where the angles don't match so it doesn't work. The latter one expects to connect to something with a 45° angle mid-connector, and the former expects a straight-on connector, and no such additional bend.

so, yeah. I could print a thing. I don't know whether I could bend a pipe or not, because the walls are pretty thick and I don't know if a pipe with that OD and that thickness can handle a bend like that without, idk, a factory or something.

Or maybe I could adopt the new 45° bike-side hitch and cut the old trailer's pipe down short like the new trailer's pipe and drill the necessary holes, and go to that system instead.

I definitely do not want to be switching out trailer hitches on the bike side every time I attach a different trailer. That's not acceptable and I shan't be doing that.

So. Anybody familiar with this situation and got an answer? Because I'm not and don't.

-

System shared this topic on

-

so, yeah. I could print a thing. I don't know whether I could bend a pipe or not, because the walls are pretty thick and I don't know if a pipe with that OD and that thickness can handle a bend like that without, idk, a factory or something.

Or maybe I could adopt the new 45° bike-side hitch and cut the old trailer's pipe down short like the new trailer's pipe and drill the necessary holes, and go to that system instead.

I definitely do not want to be switching out trailer hitches on the bike side every time I attach a different trailer. That's not acceptable and I shan't be doing that.

So. Anybody familiar with this situation and got an answer? Because I'm not and don't.

@moira I've built a few trailers, and ending up using rod end bearings/rose joints because they work... as long as the bike doesn't tip over. Which is fine for me, likely not for most others (the cargo bike has a proper stand, the quad has four wheels). I also have a welder and that answers a lot of questions :)

Pics of the two trailers and hitches would help a lot.

Also, you may be able to find a welding shop nearby who will squirt molten steel on your bits for a cheap price.

-

@moira I've built a few trailers, and ending up using rod end bearings/rose joints because they work... as long as the bike doesn't tip over. Which is fine for me, likely not for most others (the cargo bike has a proper stand, the quad has four wheels). I also have a welder and that answers a lot of questions :)

Pics of the two trailers and hitches would help a lot.

Also, you may be able to find a welding shop nearby who will squirt molten steel on your bits for a cheap price.

@moira IME the price difference between "these two bits, hot glue them along the joint" and "build me a widget" is large. Especially if you manage to look like the sort of person who has dodgy home-built bits already. Goal is to convince them that you're not going to hassle them if your idea doesn't work. Other than the obvious "here's my new idea, and some more money" thing :)

-

@moira I've built a few trailers, and ending up using rod end bearings/rose joints because they work... as long as the bike doesn't tip over. Which is fine for me, likely not for most others (the cargo bike has a proper stand, the quad has four wheels). I also have a welder and that answers a lot of questions :)

Pics of the two trailers and hitches would help a lot.

Also, you may be able to find a welding shop nearby who will squirt molten steel on your bits for a cheap price.

@moz The other trailer connector end looks exactly like the one in the first photo, but it's shorter and doesn't bend. Everything else is exactly the same.

There's no idea here. I've got this new trailer I built with a short straight pipe at the end and the old one with a longer curved pipe at the end. Everything else about them is absolutely identical and I didn't invent any of it.

-

@moz The other trailer connector end looks exactly like the one in the first photo, but it's shorter and doesn't bend. Everything else is exactly the same.

There's no idea here. I've got this new trailer I built with a short straight pipe at the end and the old one with a longer curved pipe at the end. Everything else about them is absolutely identical and I didn't invent any of it.

@moz Here's a picture of the new trailer that includes the short, straight end pipe. Everything else is identical to the other trailer, basically.

-

@moz Here's a picture of the new trailer that includes the short, straight end pipe. Everything else is identical to the other trailer, basically.

@moz Here I found a closeup of the new trailer. Same kind of deal - spring (if shorter), bolt connectors on either side of a spring, but instead of the longer curved pipe it's got a short straight pipe.

-

@moz Here I found a closeup of the new trailer. Same kind of deal - spring (if shorter), bolt connectors on either side of a spring, but instead of the longer curved pipe it's got a short straight pipe.

@moira It's hard not to say "weld this to that" but really, welding is the easy option. Find a bit of pipe that sleeves over the bicycle end, find a spring that goes inside (or outside) that pipe, weld a stub of pipe to the trailer end, bolt the spring in place, find a bit of chain that goes inside the spring and put the bolts thru that too.

I have used something similar, without the quick release, I just pop the nut off the axle of the bike and remove the whole hitch

https://moz.geek.nz/mozbike/build/megatrailer/index.html -

@moira It's hard not to say "weld this to that" but really, welding is the easy option. Find a bit of pipe that sleeves over the bicycle end, find a spring that goes inside (or outside) that pipe, weld a stub of pipe to the trailer end, bolt the spring in place, find a bit of chain that goes inside the spring and put the bolts thru that too.

I have used something similar, without the quick release, I just pop the nut off the axle of the bike and remove the whole hitch

https://moz.geek.nz/mozbike/build/megatrailer/index.htmlTerrible Pinta art for you :)